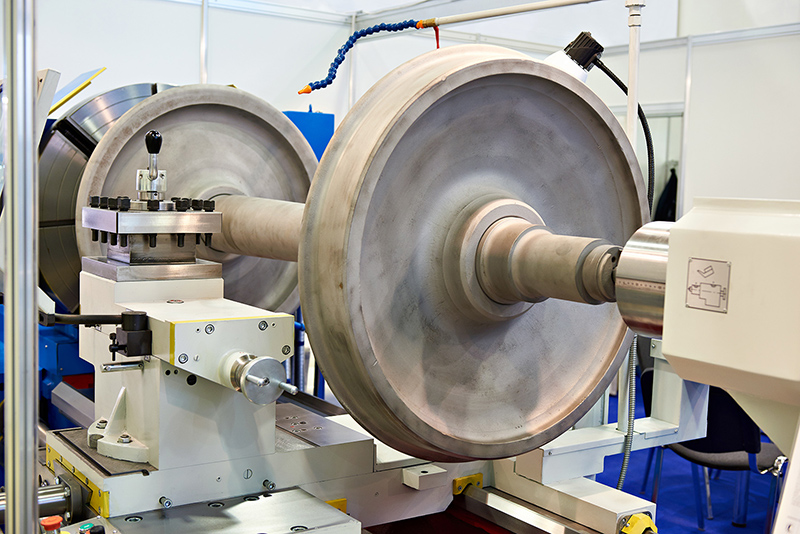

Double row cylindrical roller bearings

With a wide range of executions of double row cylindrical roller bearings, RKB is able to fulfill any requirement in demanding applications such as large size gearboxes, machine tools, grinding mills and crushers. To ensure superior performance, RKB double row cylindrical roller bearings are manufactured from high quality special steels, heat treated in optimized automatic lines. With improved internal geometry and profile, they can withstand high radial loads within a narrow cross section.

Main types

-

Type NNU

- Outer ring with three integral ribs

- Ribless inner ring

- One-piece double pronged machined brass or steel cage

- Annular groove and lubrication holes in outer ring

- Optimized raceway geometry and roller profile

- Available with cylindrical and tapered bore

- Available with locating slots in outer ring, lubrication holes in inner ring, lubrication grooves in side faces of inner and outer rings

- Available with steel pin-type cage and pierced roller design

-

-

Type NN

- Ribless outer ring

- Inner ring with three integral ribs

- One-piece double pronged machined brass cage

- Annular groove and lubrication holes in outer ring

- Optimized raceway geometry and roller profile

- Available with tapered and cylindrical bore

- Available with steel pin-type cage and pierced roller design

-

-

Type NNUP

- Outer ring with two integral ribs and one loose rib

- Inner ring with one integral side rib and one loose rib

- One-piece double pronged machined brass or steel cage

- Annular groove and lubrication holes in outer ring

- Optimized raceway geometry and roller profile

- Available with locating slots in outer ring, lubrication holes in inner ring, lubrication grooves in side faces of inner and outer rings

- Available with steel pin-type cage and pierced roller design

-

-

Type split SCRB

- Design used for medium and large size bearings

- Two wider inner ring with integral side ribs

- Two-piece window type for each bearing row

- Engineered for hard-to-reach positions (e.g. universal joint drive shaft supporting)

- Design for easy mounting, dismounting and maintenance to reduced machine downtime

- Available in locating and non-locating configuration

-

-

Type NNUB

- Outer ring with three integral ribs

- Wider ribless inner ring

- One-piece double pronged machined brass or steel cage

- Annular groove and lubrication holes in outer ring

- Optimized raceway geometry and roller profile

- Available with locating slots in outer ring, lubrication holes in inner ring, lubrication grooves in side faces of inner and outer rings

- Available with steel pin-type cage and pierced roller design

-